Last Updated on October 25, 2024 by Ellen

The first month’s electric bill: 360 Philippine Pesos — $7.29.

That is the tally from the dedicated electric meter for our new drinking water pump serving the small indigenous Ati tribal village near our temporary Covid-crisis home in Malay, Aklan, Panay, Philippines.

I’m very pleased at the modest amount – and confident the 23 Ati families who are using the convenient water faucets (instead of making a long hike and carrying heavy jugs) will be able to pay it.

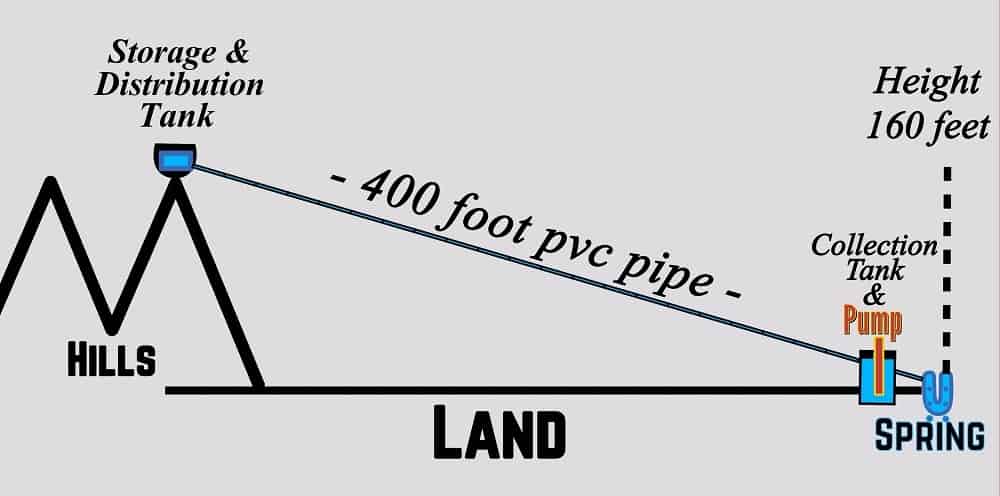

As a reminder, we sponsored the drinking water project. It took a half-year to complete. Below is a graphic summarizing the challenge.*

During that time, with help from overseas donors, we acquired the necessary system pieces and parts. One month ago the water started pumping and flowing.

Yesterday, AKELCO, the local electric cooperative, read the Ati electric meters and distributed bills. There had been some tribal anxiety about what the first water pump bill would be.

But I had been reading the meter during my repeated visits in June – when I was checking the new system on a near daily basis. I knew the usage was about one kilowatt per day. At the standard rate of about 12 pesos per Kw (25 cents), I expected the bill to be 350 to 400 pesos total.

Still, it is good to have confirmation and the first bill in hand. Hopefully, all the involved families will pony up their shares in timely fashion.

And sure, I am tempted to pay it myself – a small gift for the Ati community; a celebration of our successful water project. But doing so could be counterproductive: establish unwise expectations; encourage water waste; create dependency.

Best to let the Ati themselves sort it out. After all, they will have to do so in the future when we are not here – and hopefully for many many more years thereafter.

Actually, each time I noted the slowly rising meter reading I was more pleased with the model pump that we ended up using. The USA made, submersible deep-well pump contains a three-fourths horsepower motor. Electrical use when engaged is about 550 watts. It is very strong and efficient.

The alternative, which I initially favored, was an above-ground jet pump. Those type pumps are far less efficient. We would have needed a 2 horsepower motor running at 1500 watts. The monthly electric bill would be triple – at least.

Indeed, for the height (head) we needed to pump the water, the jet pump would have struggled. The outflow would have been slower/less. The pump would have had to run much longer to fill our upper holding tank, further increasing electric consumption.

Another benefit to the submersible deep-well pump, the issues of suction and priming are negated. A jet pump sits outside the water source and sucks (vacuums) water into an impeller on one side, then discharges (pushes) it out the other with force. The process is inefficient.

Further, when the pump stops, water tends to back flow out of the suction hose/pipe. Air can enter the system causing pump damage when it kicks on again. Check valves are used to prevent such an occurrence, but priming is a frequent concern. Submersible pumps avoid it completely.

Lastly, the one real worry related to our modified submersible pump is the collection tank water level. The pump is designed to be down in a drilled bore hole – constantly surrounded by ground water. We’ve put it in a surface tank which could potentially run low/dry. If the water level ever gets below the pump intake, overheating and catastrophic failure is likely.

To prevent this, we rely on a float switch. It’s a simple, durable, reliable plastic float with a mechanism inside that opens or closes the pump electrical circuit based on the ’tilt’ of the float in the water. The switch we have is rated for 50,000 on/off cycles. It cost only $15 and works perfectly. It’s not an exaggeration to say, it is THE most crucial piece in the whole system.

Finally, so that we don’t completely rely on the mechanical float switch, I am working to devise a visual float gauge on the upper tank exterior.

Thereby, when the pump is turned on at the top control panel as usual, the operator would be able to accurately know the water level inside the concrete tank – even though it can’t be seen directly.

When the gauge shows sufficient fill level, the operator would turn off the pump – before the float switch cut-off is activated. Thus the float switch would become a back-up / safety. I expect to have the gauge workable within the next two weeks.

In all, the drinking water collection, pump, and distribution system continues to operate smoothly and efficiently. It took months of research, consultation, and contemplation to arrive at the final design.

Now after receiving the first electric bill, the deep-well style pump, modified for our above-ground collection tank, has proven to be the best choice. The monthly electric bill should continue to be $6 to $8.

As always, be thankful and generous, happy trails & more beer.

Life is NOW!

(*Editor’s note: the graphic was updated on July 17, 2021, to indicate where the collection tank and pump are located.)

???. Good for you Tedly

Very cool project! So great that you could help them. If the pump is in the tank, how does the water get up the 420′ from the spring to the tank? Are the end users up in the hills?